Number of cavity : Four Cavity

Plastic material : ABS HI-121

Analysis type : Flow/Pack/Warp

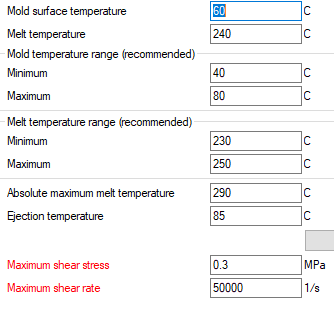

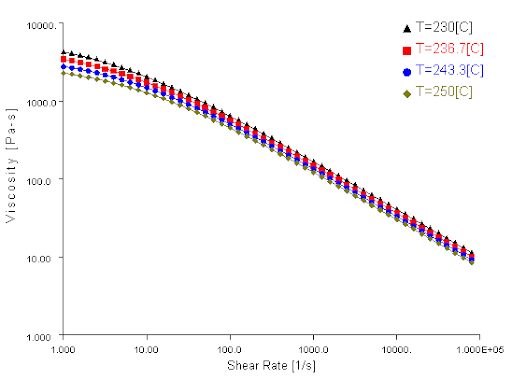

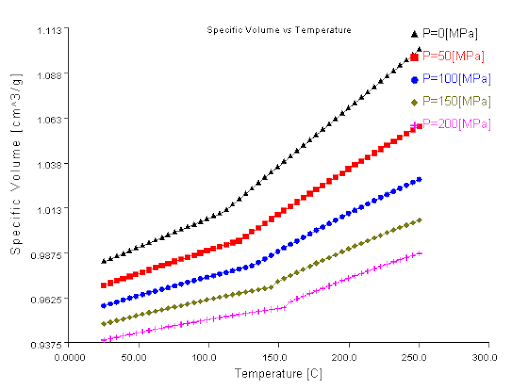

The material data is from moldflow database and shown in the pictures below

Recommended

Processing:

Rheology:

PVT properties:

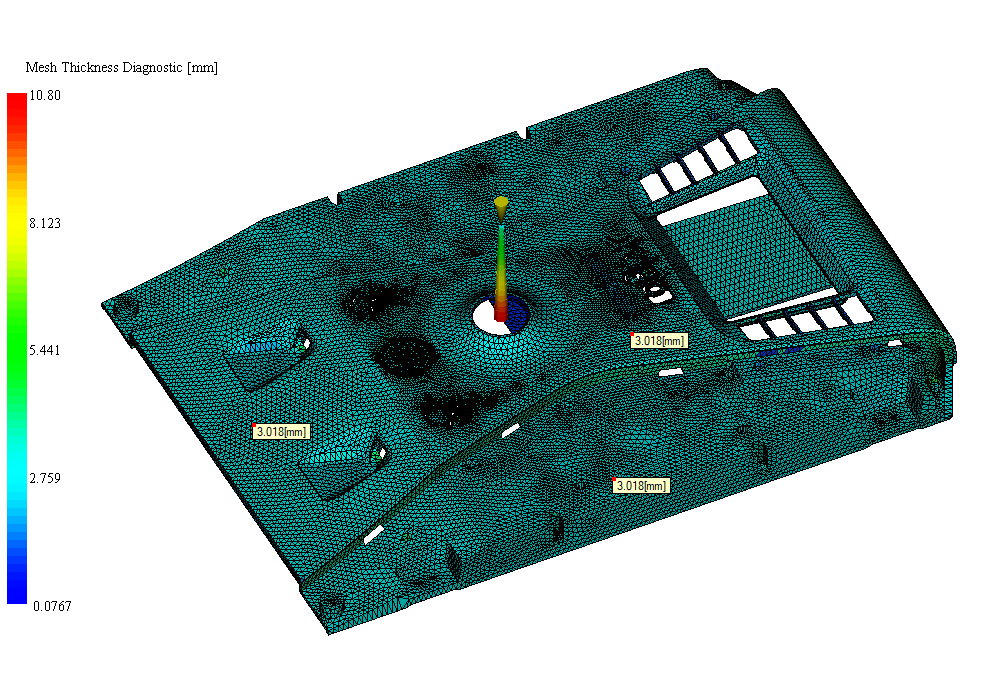

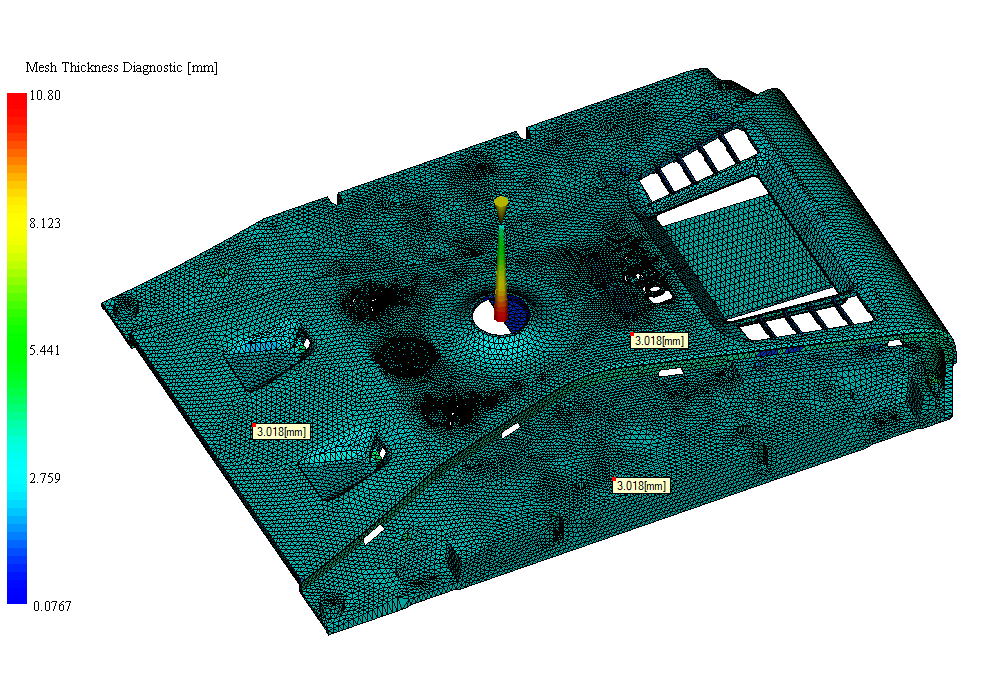

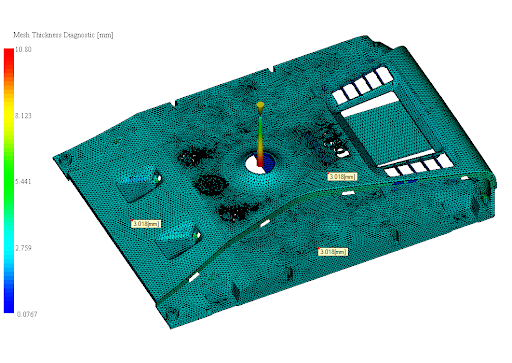

Model Information

- Product Model introduction

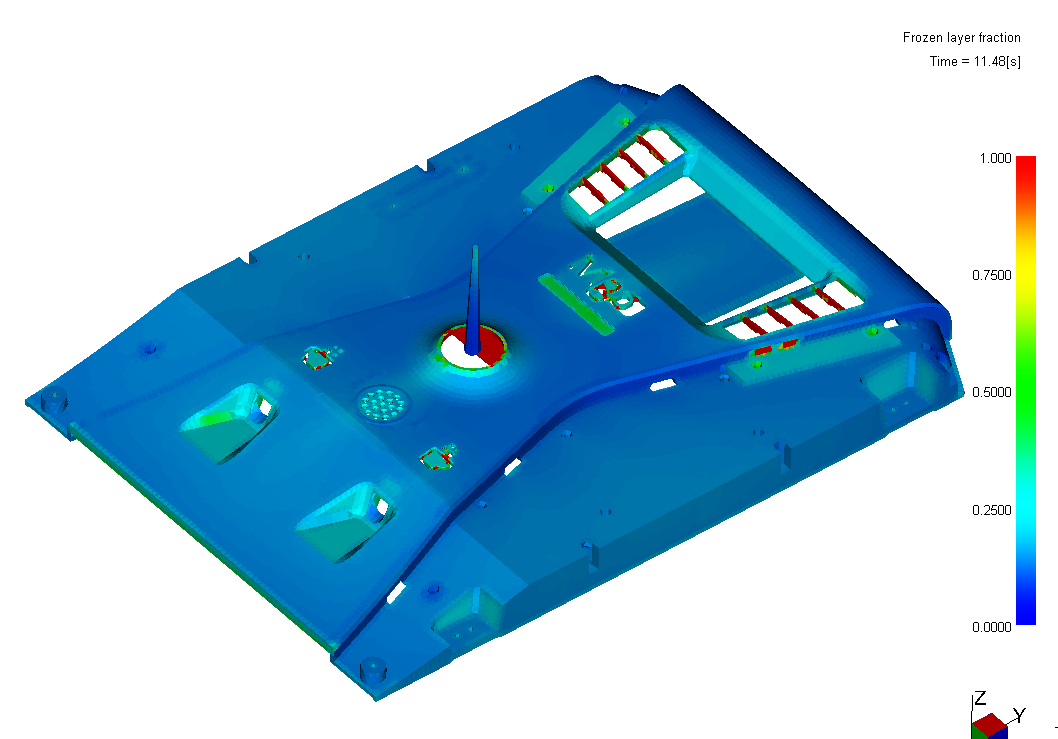

- Gate Freeze time = 11.48 sec

- Material

ABS HI-121

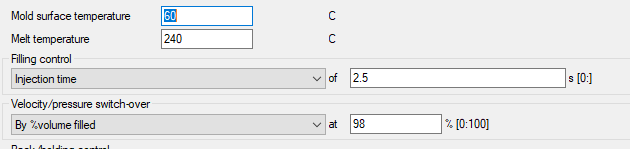

- Process Setting

- Fill time : 2.5sec

- Melt temperature: 240°C

- Mold temperature: 60°C

- Max. Injection Pressure :107MPa

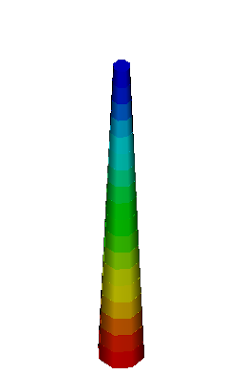

Feed System Details

Sprue Gate

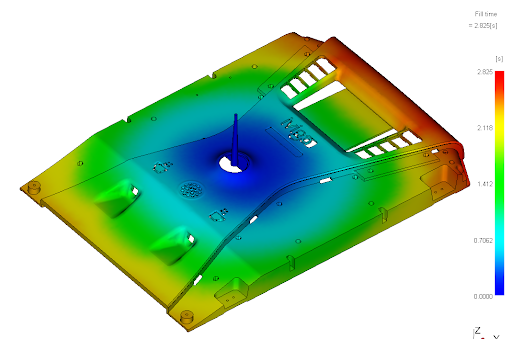

Fill Time:

Flow pattern is uniform without short shot or hesitation, more than 90% balance observed in the component

Fill Time(sec) Animation:

Flow pattern is uniform without short shot or hesitation, flow pattern is acceptable.

Flow pattern is uniform without short shot or hesitation, flow pattern is acceptable.

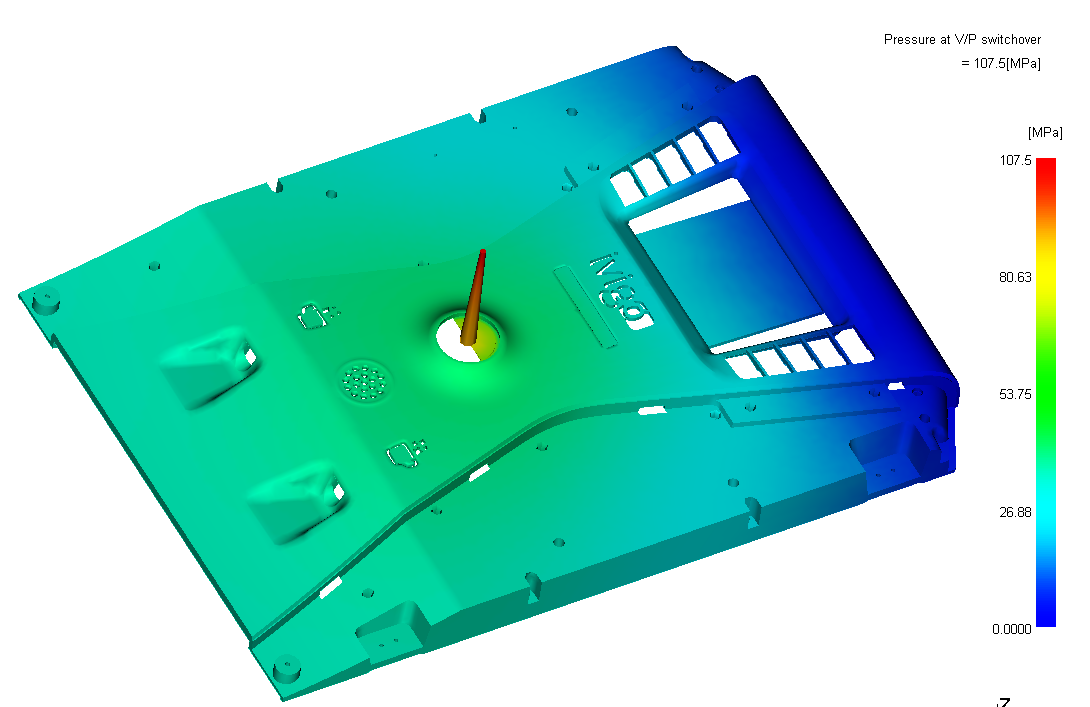

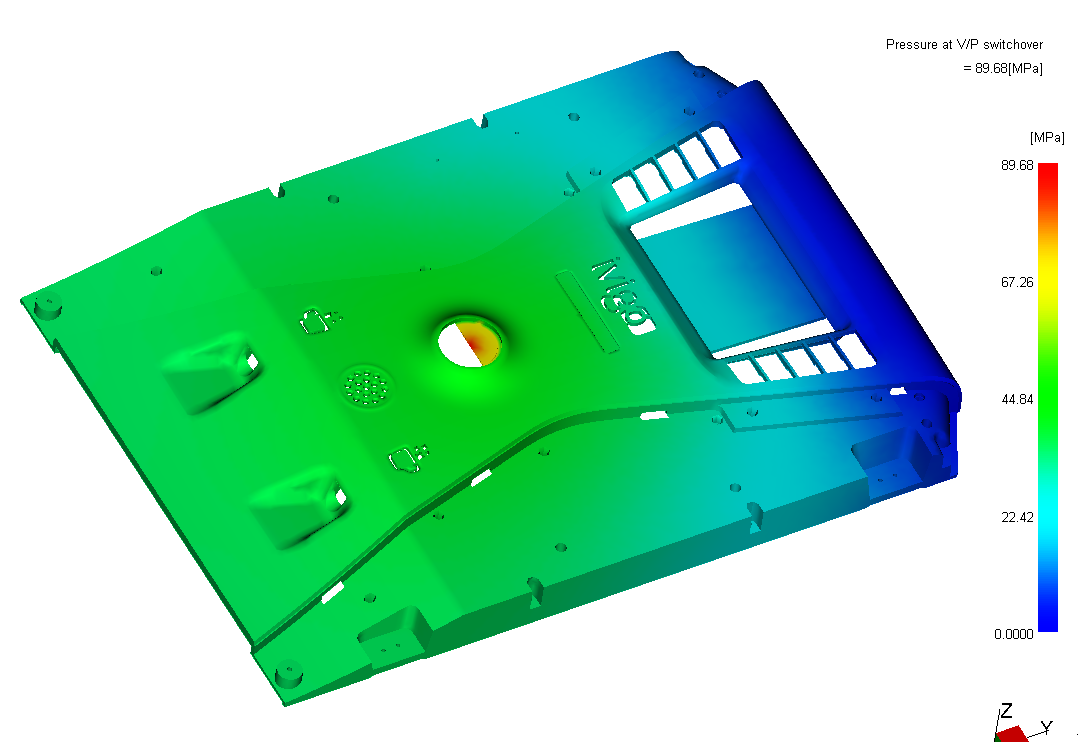

Pressure at V/P switchover

The maximum injection pressure is 107MPa. This is considered to be good

The maximum injection pressure in component is 89MPa

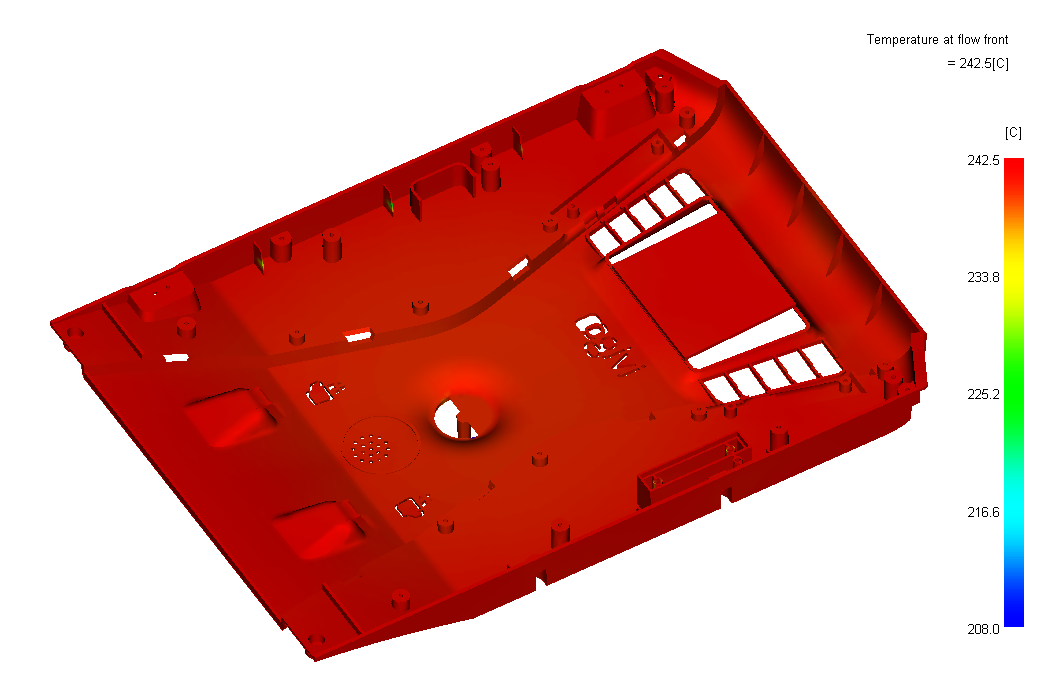

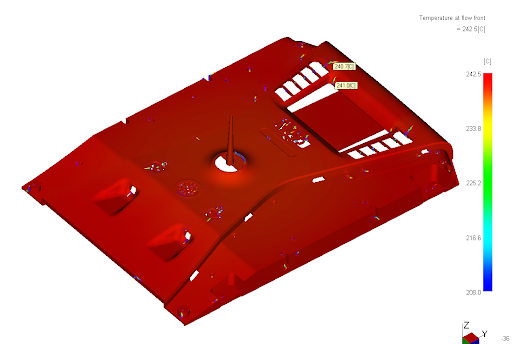

Temperature flow front

Temperature drop observed is within 10 deg C

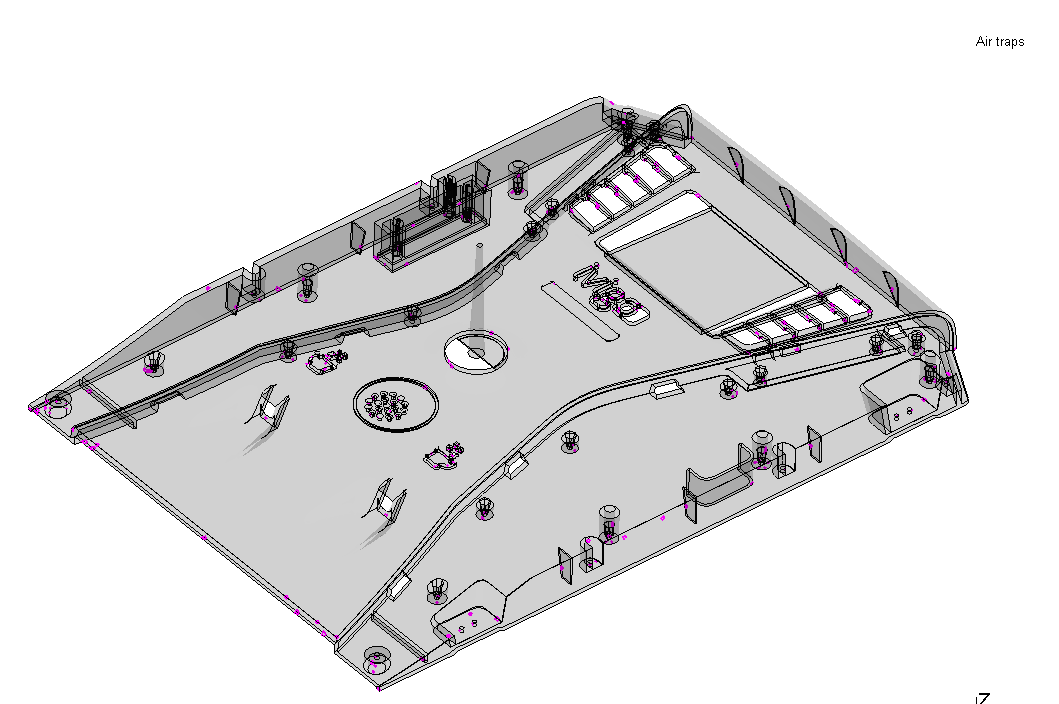

Air trapped area

Please add enough venting at the marked area.

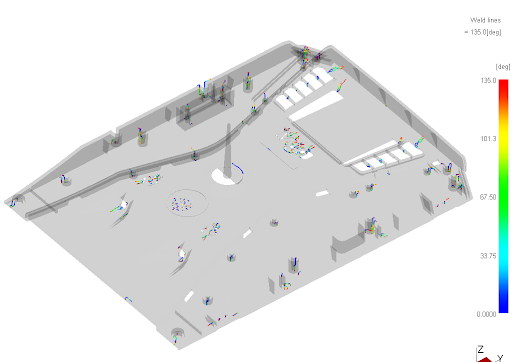

Weld lines

Plot Shows Weld line will fuse at higher temperature except at circled are where there is slight drop in temperature observed

Temperature Plot Overlaid with Weld Line

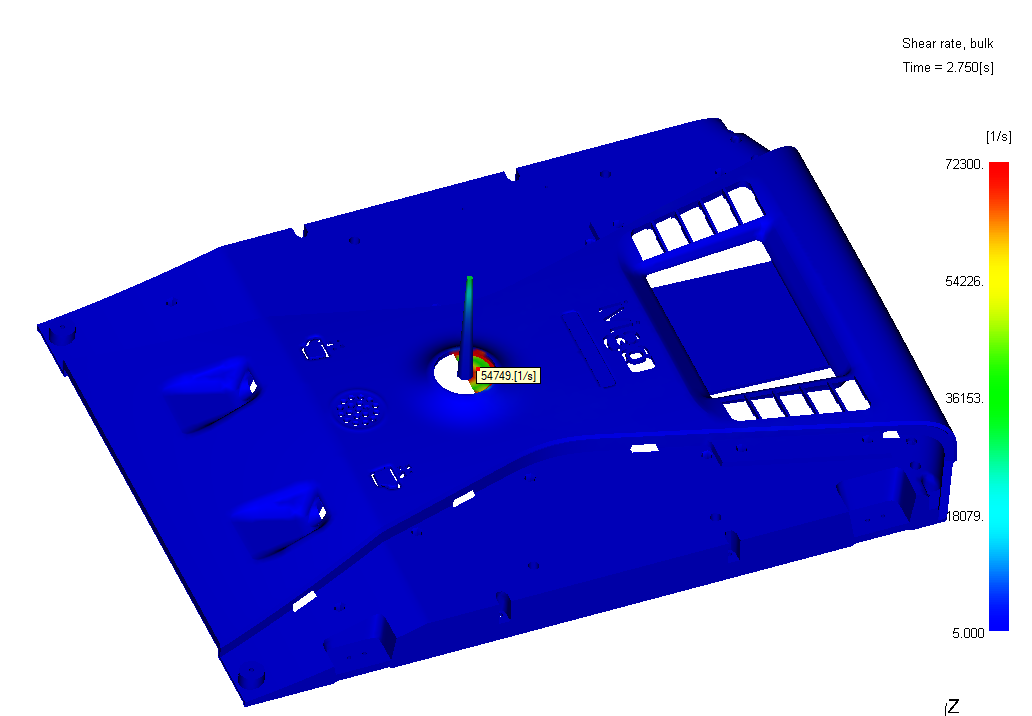

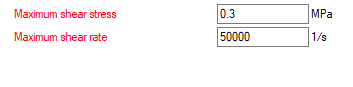

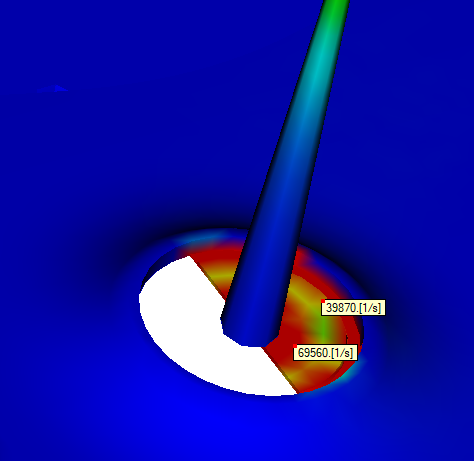

Maximum shear rate

Increase the thickness to avoid shear heating

Max. shear rate=48500 1/S is lesser higher than specified 50000 1/S but still higher shear heating is seen . Suggested to increase the thickness near gate area

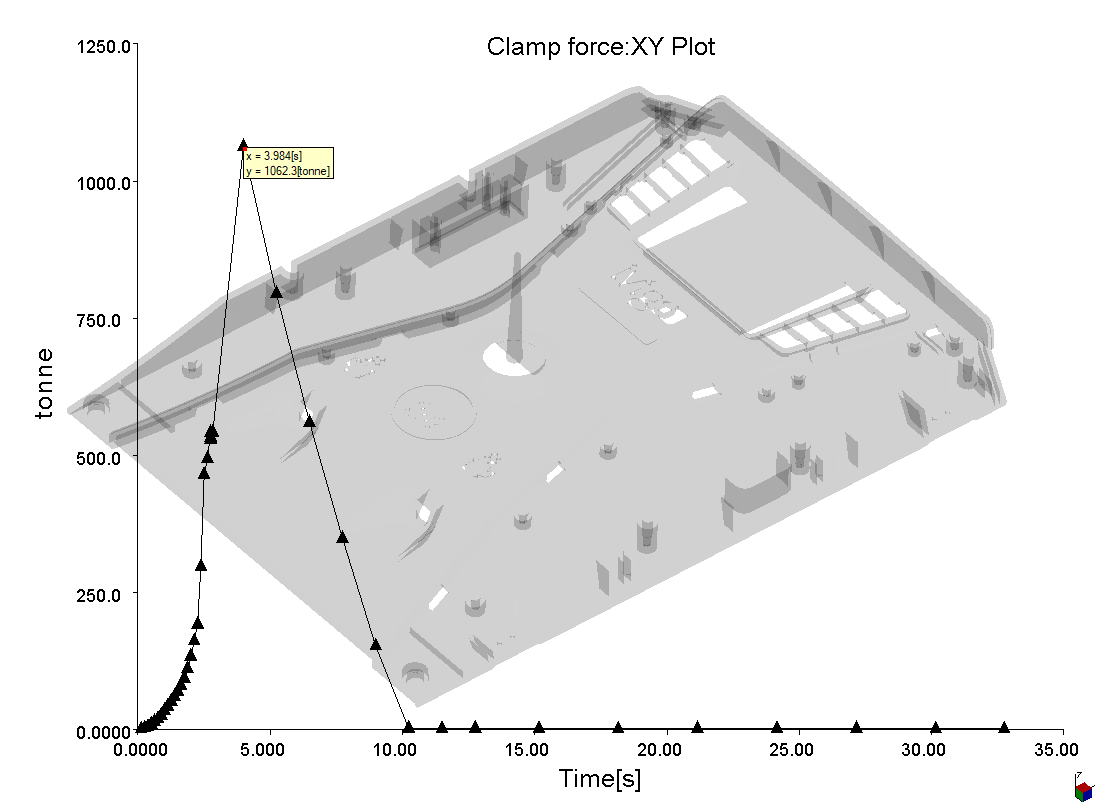

Clamp force

The maximum clamp force is 1062 Tonne during packing

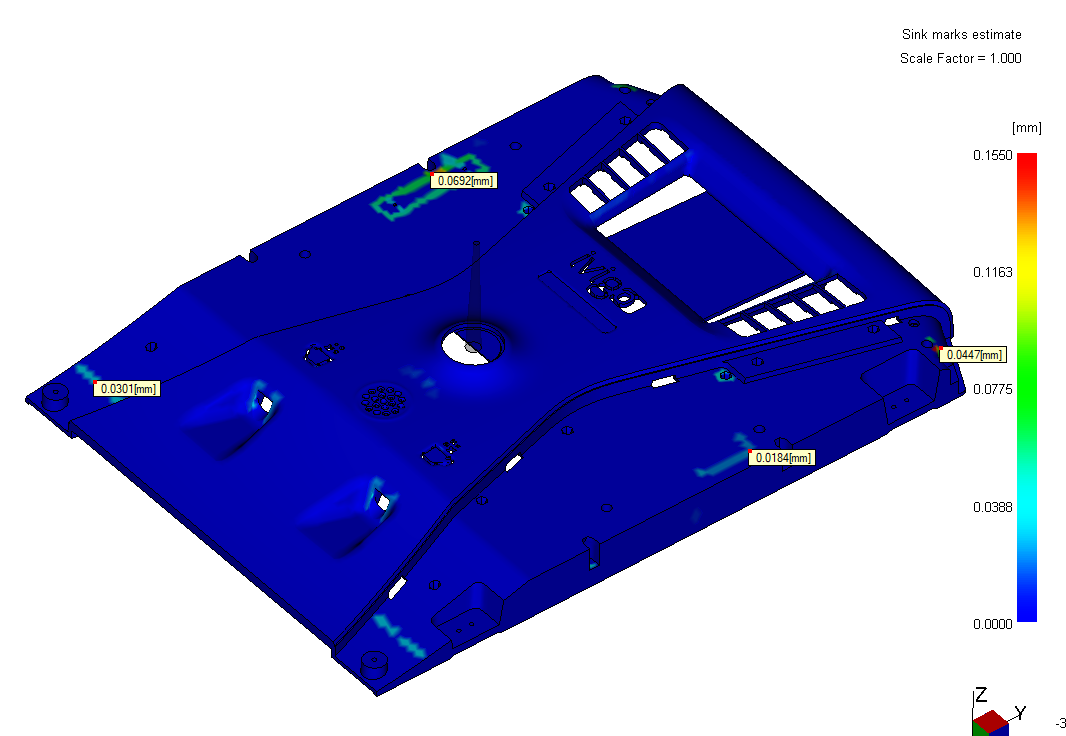

Sink mark

Sink mark depth is less and can be controlled by applying proper packing pressure

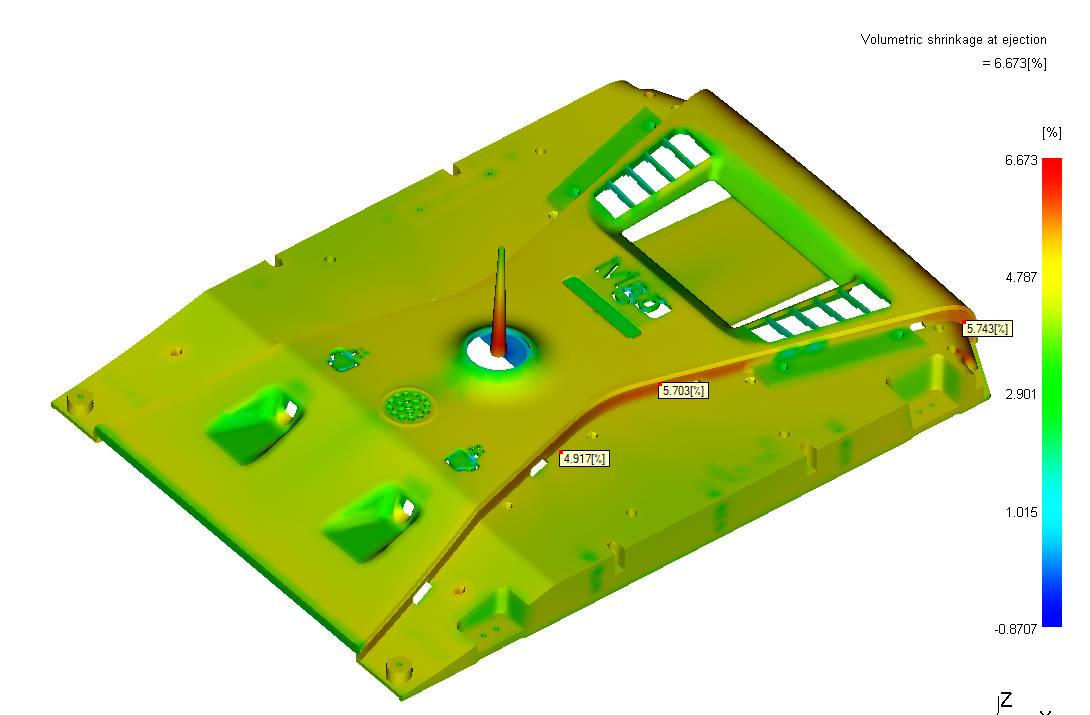

Volumetric shrinkage

Shrinkage is uniform, marked area has big shrinkage, suggest to use higher packing to eliminate any possibility of sink mark.

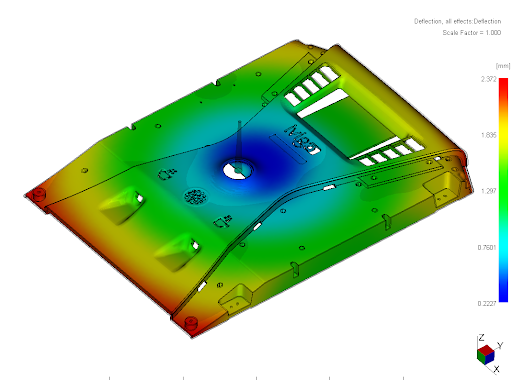

Deflection, Total

Total warpage is about 2.3 mm,including shrinkage

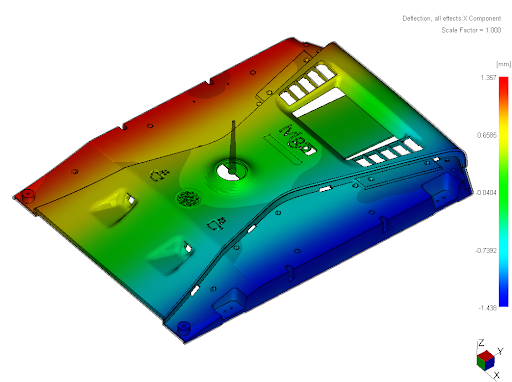

Deflection: X direction

Warpage in X direction is 1.35mm

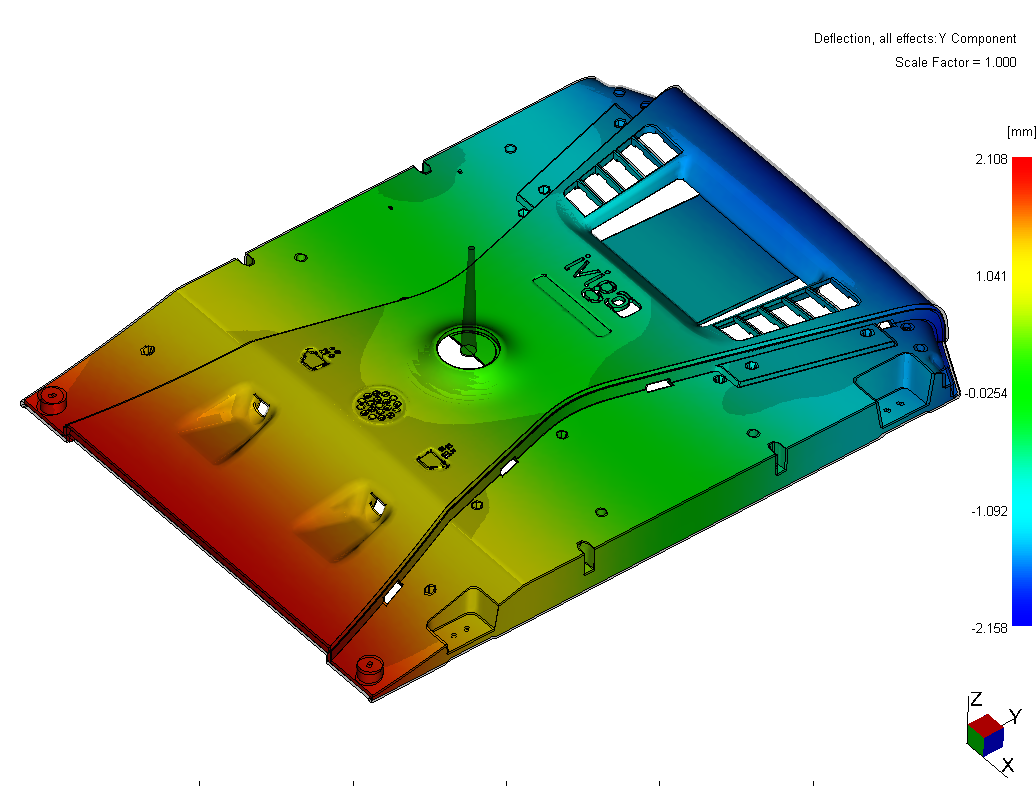

Deflection: Y direction

Warpage in Y direction is about 2.1mm

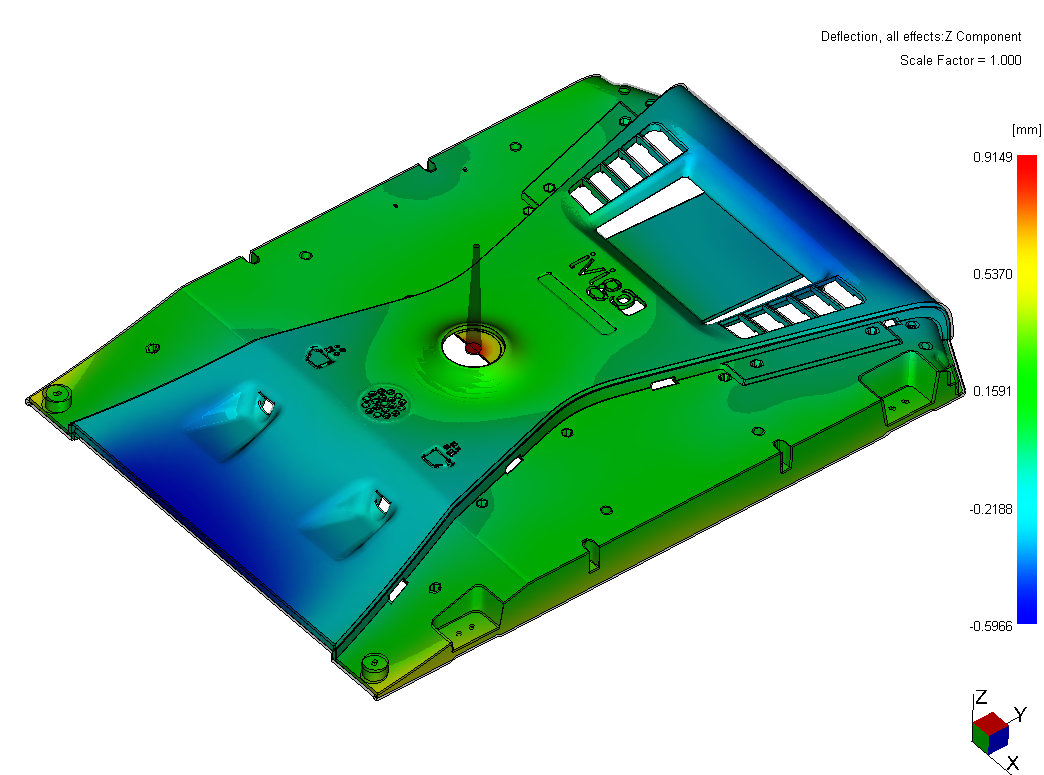

Deflection: Z direction

Warpage in z direction is about 0.91mm

Gate Freeze Time

Frozen time= 11.48 s.

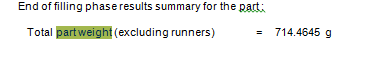

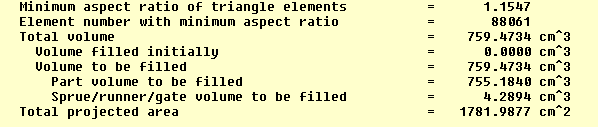

Part Weight

Total Part Volume to be filled = 759 cm3

Summary

We have performed several filling, cooling and warpage analysis on the four cavity The aim of the Analysis was to have a set of processing conditions that would enable a large molding window to be obtained, thereby allowing variations to the molding parameters for the quality aspects of the part and analyzing characteristics of the product. The following facts can be concluded.

- The flow Analysis of part showed no major problems during filling using specified material

- Pressure requirement is 107MPa. This is considered as high considering wall section variation, flow length & raw materials

- The Flow Front temperature has 10°C variation over majority of components, which is considered as a very good scenario and should maintain excellent weld line strength & provide moulder wide moulding window to fine tune parameters.

- Shear stresses are within specified limit in majority of component area.

- Provision should be made in the tool for venting as shown in plots. This is to be noted by tool maker.

- Meld lines formed due to flow merging and noted by tool maker to provide air vents in that location.

- Clamp tonnage required to fill this part is 1062 tones

- No sink mark observed on filling with higher tonnage machine. Possibility of Sink Mark Can be avoided by applying proper decaded packing profile